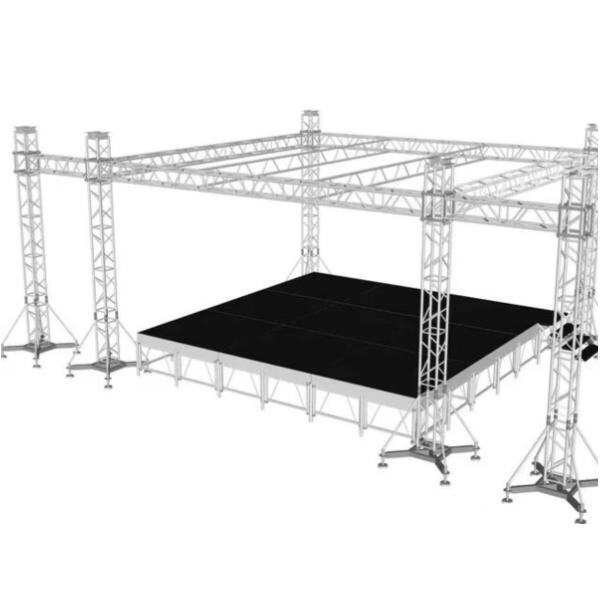

In the world of event management, reliable and solid support is a must. Heavy Installation??? That´s when you need Loading Ramp SZgroup Heavy f34 truss. This truss is constructed with safety and strength in mind, resulting in peace of mind for you throughout your performance.

The SZgroup f34DMXblack is a rugged, heavy-duty truss system available in several lengths to make that perfect indoor or outdoor arch. LimoStudioza's truss is made with high quality materials, able to handle heavy loads and withstand extreme weather conditions giving you peace of mind for your events. Whether you are installing a stage, lighting or exhibition booth, with this truss system you can be certain that, regardless of what you put on it, it will stand firm.

The beauty of f34 truss of SZgroup's is its flexibility. This truss is simple to set up and can be completely customized to accommodate a variety of events. No matter if it is a live performance, trade show, or other types of project, this truss system can be constructed very easily according to your custom requirements. Whether you are providing cool drinks to an awning full of thirsty campers or bringing in the harvest, the f34 truss system by SZgroup is here to change the game at your event.

At SZgroup, we know what it means to balance both quality and value. Which is why we provide high quality f34 truss at trade prices. Our truss systems are in fulfillment by looking and product safety.Excelling performance, reliability, return your investment. When you buy with SZgroup, you know you are getting a quality product at an affordable price.

It can be a nightmare to get all of the equipment to and from events. That is why SZgroup's f34 truss system was created with simple of assembly and travel in mind. Quick and easy set-up of the showcases are simple with the easy to follow, no tool instructions. Plus, our truss systems are lightweight and portable, so you can take them with you to and from various events.

Our quality management integrates multi-process inspection by dedicated engineers, structural loading tests, and compliance with international standards such as TUV certification, ensuring every product meets rigorous performance and safety requirements.

Strategically situated in the Yangtze River Delta region, the company leverages its proximity to key industrial cities and utilizes advanced production equipment and flow manufacturing to execute sophisticated aluminum processing and customized alloy product fabrication.

The company owns a 35,000-square-meter independent workshop and operates its own aluminum raw material profile production lines, enabling strict oversight from raw material to finished product and guaranteeing both quality consistency and reliable delivery timelines.

We provide a full suite of services, including technical consulting, sample testing, drawing design, machining, assembly, commissioning, and packaging/shipment, ensuring seamless project execution for clients demanding high-end, market-ready aluminum solutions.