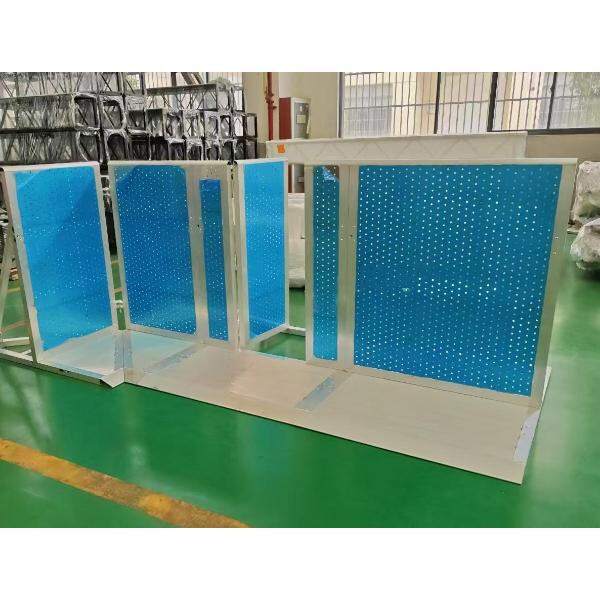

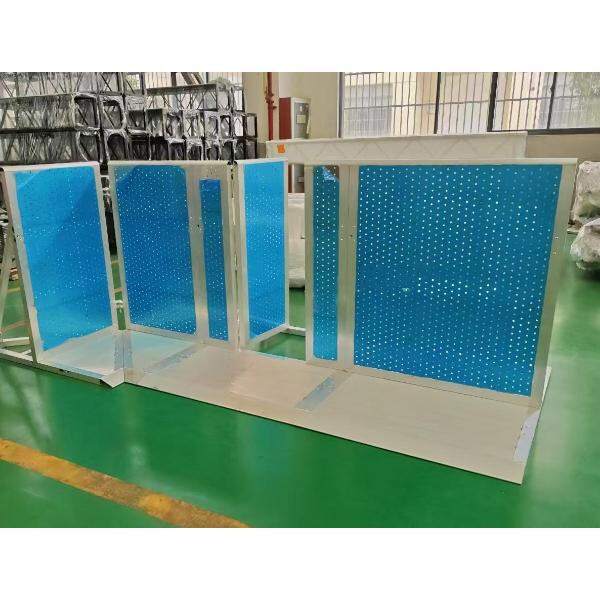

In planning events or overseeing mass gatherings, the safety and security of those involved is of utmost importance. This is where SZgroup’s Aluminum Barrier crates come in. Part of New ZP RangeOur barrier crates are new from the ZP range of products and are tailor made to offer a cost effective and well-designed solution to crowd control in a variety of environments.

One of the things that separate SZgroup barricade crates from other is the build quality with these great materials you can be guaranteed for a long-lasting performance. This barrier crate is durable enough for multiple uses, continuing to stand up to the typically rough and tumble environment. From open air concerts to sporting events, this barrier crate will take anything you throw at it, and perform.

SZgroup supply a range of bulk barrier crate order options which you can tailor to suit the specific orders. Whether you want to change the color, size, or pattern, with SZgroup customization can vary. This versatility means that customers will have access to barrier crates that meet their exact requirements.

SZgroup’s barrier crates are an amazing product for event planners and security companies. These crowd control crates are a dependable and efficient solution to crowd control and safety of patrons. Including such barrier crates in their planning enables the event organisers to provide a safer and more organised environment for competitors.

Low wholesale price for bulk orders is a feature of SZgroup barrier crates. This price tier also makes it easy on customers to purchase 10, 20, or 25 of these inexpensive barrier crates to hurdle dogs. Hoppers are perfect for crowd control needs at any little event or big festival.

We provide a full suite of services, including technical consulting, sample testing, drawing design, machining, assembly, commissioning, and packaging/shipment, ensuring seamless project execution for clients demanding high-end, market-ready aluminum solutions.

Our quality management integrates multi-process inspection by dedicated engineers, structural loading tests, and compliance with international standards such as TUV certification, ensuring every product meets rigorous performance and safety requirements.

The company owns a 35,000-square-meter independent workshop and operates its own aluminum raw material profile production lines, enabling strict oversight from raw material to finished product and guaranteeing both quality consistency and reliable delivery timelines.

Strategically situated in the Yangtze River Delta region, the company leverages its proximity to key industrial cities and utilizes advanced production equipment and flow manufacturing to execute sophisticated aluminum processing and customized alloy product fabrication.